Flexible and captive laser marking in all dimensions for batch size 1 to infinite

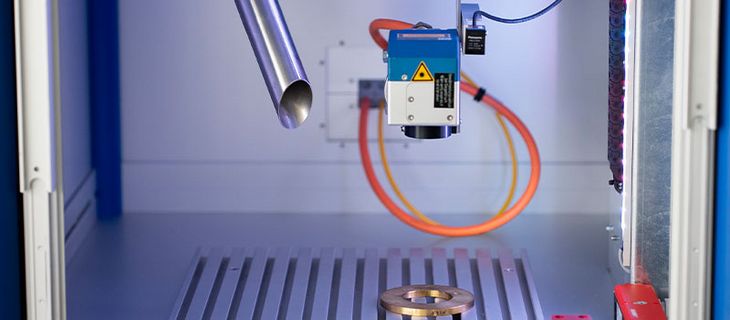

Premiere at Fakuma: Reliable and precise product marking with the REA JET FL Laser Marking Cabin

Mühltal, Germany, October 6, 2021 - Global marking and code verification specialist REA Elektronik will present its new laser marking cabin for high-quality marking of materials at Fakuma 2021 from October 12 to 16. Thanks to its modular design, it can be customized - at the price of a series product.

The extremely versatile concept of the laser marking cabin from REA Elektronik enables solutions ranging from stand-alone manual workstations to fully automated, networked marking stations. Both the cabin design and the pulsed fiber laser allow maximum flexibility for reproducible, high-quality product marking on plastics, but also metals or ceramic materials. For this purpose, the REA JET FL Laser Marking Cabin can be optimally adapted to the customer's needs - from the size of the process chamber to the laser power and the placement of the marking field to the type of material supply and removal. With the autofocus function in combination with the motorized Z-axis, users can work much more efficiently with frequently changing component geometries and reduce the risk of rejects.

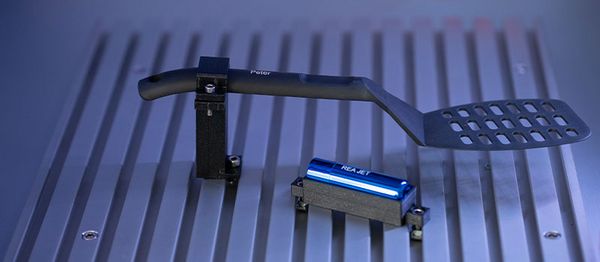

At the REA JET booth, Fakuma visitors will experience an individual marking application created in cooperation with compound specialist AKRO-PLASTIC - and can take the product home as a souvenir: Using color change, the REA JET Fiber Laser marks a plastic spatula into whose material laser-sensitive additives have been incorporated.

Industrial users can intuitively create the application for the laser marking cabin using the REA JET TITAN Platform. They can also use it to control all REA Coding and Marking Technologies (ink, paint, label or laser), which significantly reduces training and staff planning costs, especially in companies with diverse coding needs. With its state-of-the-art interface architecture, the TITAN Platform can also be integrated into production and the company's own ERP system for higher-level control.

"With the flexible laser marking cabin REA JET FL, REA resolves the conflict between series product and special machine construction. We offer our customers optimally adapted marking processes based on proven industrial components that are at the same time Industrie 4.0-capable and function as a stand-alone solution," says Michael Neuschäfer, Managing Director of REA Elektronik GmbH. "Regardless of whether our customer is marking the finest electrical contacts, pacemakers or entire motor housings, he gets an individual solution at a series product price."

Visit REA Elektronik at Fakuma 2021, International Trade Fair for Plastics Processing, from 12 to 16 October in Friedrichshafen: Hall A4, Stand 4119.