REA JET UP

Högupplösta piezobaserade bläckstråleskrivare

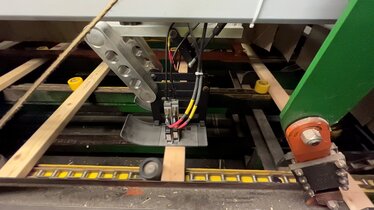

Piezo-skrivaren REA JET UP (Universal Print) är ett innovativt, högupplösta och helt nyutvecklat system för direktmärkning. Denna allroundmaskin möjliggör kontaktfri skrivare på en mängd olika ytor, t.ex. papper, kartong, trä, belagda och målade ytor.

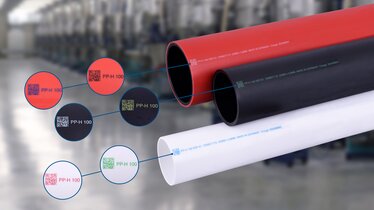

- Alfanumeriska texter: Skriva ut texter, serienummer, produktinformation eller säkerhetsinstruktioner på olika ytor.

- 1D streckkoder, 2D-koder och maskinläsbara koder: Märkning av förpackningar för identifiering, spårbarhet, kvalitetskontroll och höga första inläsningstillfällen för effektiv hantering av flödes- och lagringsprocesser.

- Logotyper och piktogram: Applicering av företagslogotyper, faro-/säkerhetsskyltar, produktbilder och grafiska element för varumärkeskommunikation, säkerhet och produktpresentation.

- Variabel data: Skrivare för datum, tid, räknarställningar, skiftkoder och databasinnehåll för spårbarhet, kvalitetskontroll och lagerhantering.

- Spårbarhet: Skapande av unik märkning för att spåra produkter genom hela leveranskedjan.

- Sekundära förpackningar: Märkning av sekundärförpackningar, t.ex. kartonger och papplådor, för optimerad lagerhållning och logistik.

- Förpackningsmärkning: Används inom förpackningsindustrin för märkning av produktförpackningar, både på primär- och sekundärförpackningar.

- Logistikindustrin: Används inom logistikindustrin för att identifiera och spåra varor i transit, skriva ut fraktetiketter och förbättra lager- och inventariehanteringen.

Upptäck de många möjliga användningsområdena för vårt högpresterande REA JET UP system för kodning och märkning, som du kan använda för att säkerställa utskriftskvaliteten i din bransch.

Den mångsidiga REA JET UP (Universal Print) är en robust, högupplösta piezobaserad bläckstråleskrivare.

Dagens industriföretag står inför allt större utmaningar när det gäller precision, effektivitet och spårbarhet. En nyckelteknik som uppfyller dessa krav är Piezo bläckstråleskrivare, även känd som PIJ. REA JET High Resolution Inkjet Printer är en högupplösta bläckstråleskrivare som är särskilt utvecklad för direkttryckssystem och säkerställer högsta kvalitetsstandard i moderna produktionsmiljöer.