Siste nytt fra verden av systemer for merking, etiketteringsmaskiner og kodeverifisering

I nyhetsseksjonen vår kan du finne ut alt du trenger å vite om den nyeste utviklingen, teknologien og trendene innen industriell merking og kodeverifikasjon. Hold deg oppdatert om innovative løsninger, beste praksis og viktig informasjon.

Filtrer etter kategorier

Casestudier

Pålitelig merking for hippe blandingsdrikker

Messe

Farget merking av gummidekk

Messe

Sofistikerte konsepter for industriell merking og kodeverifikasjon

Messe

Merking, kodeverifikasjon og fukting av høy kvalitet for produksjon av metallplater

Messe

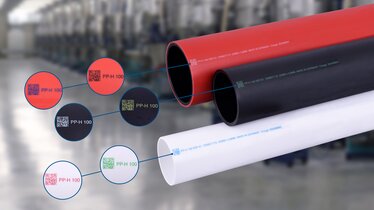

Moderne plast, høy kvalitet og variabel merking

Messe

Bærekraftig ettermontering av trykkpresser for tilpasset innhold

Produkter

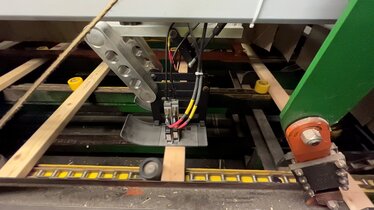

Kraftig slagbeskyttelse for REA JET HR: Uovertruffen sikkerhet i treindustrien

News

Skreddersydde etiketteringskonsepter for moderne emballasje

News

Den nye elektrisk styrte sprayblokken REA JET ST SRP-10

News

Pålitelig merking for treverdikjeden

News

Lederskifte i REA Elektronik innleder en ny æra

News

Kvalitet først - det må merking av farmasøytiske og medisinske produkter av høy kvalitet også være