REA JET GK 2.0

High-resolution inkjet printers based on piezo technology

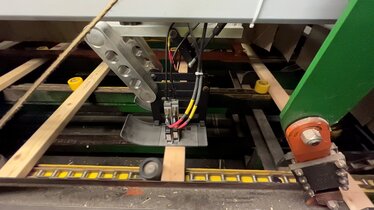

The piezo-based, high resolution REA JET GK 2.0 coding and marking system is suitable for direct, high-contrast marking on absorbent and porous surfaces such as wood, cardboard or paper with a variable print height of up to 100 mm.

Our REA JET GK 2.0 piezo inkjet printer (PIJ) is suitable for versatile applications in industrial coding and marking. Here are some examples of areas of application:

- Porous and absorbent surfaces: paper, cardboard, wood, textiles, nonwovens, building materials, etc.

- Flexible alternative to labels and pre-printed cardboard packaging

- Serialization and Track & Trace applications

- Qualitative code verification in one process with verification systems from REA VERIFIER

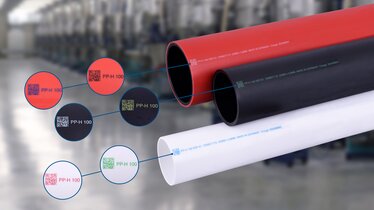

- Alphanumeric texts, machine-readable 1D and 2D Codes and logos

- Variable data such as date, time, counter, shift code, database contents, etc.

Discover the versatile possibilities offered by our powerful REA JET GK 2.0 coding and marking system to ensure print quality and traceability in your industry.

The piezo-based Inkjet Printer (PIJ) is suitable for marking on absorbent surfaces

This revolutionary printer sets new standards in printing technology and offers numerous advantages that make it particularly suitable for industrial applications. One of the outstanding aspects of the REA JET GK 2.0 is the use of solvent-free inks. This environmentally friendly solution not only ensures clean production processes, but also health-friendly working conditions.