REA JET ST

Spray mark systems

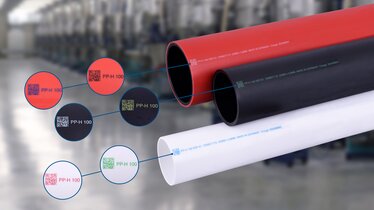

Innovative solution for large-area product marking. With electrically controlled spray mark heads, the SRE-10 spray mark block produces very large, clearly readable markings up to 206 mm. Ideal for material designations, batch numbers, 2D Codes and logos as well as the precise application of primers and process fluids.

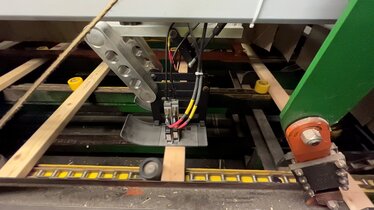

The REA JET ST spray mark system is the ideal solution when products have to be clearly readable marked with paints and varnishes from a distance. To produce very large, clearly readable alphanumeric markings, electrically controlled spray mark heads are combined to form a spray mark block - the REA JET ST SRE-10. This innovative technology enables the marking of information such as material designations, batch numbers, 2D Codes and logos at a print height of up to an impressive 206 mm, as well as the precise application of primers and process fluids.

Especially in the aluminum and steel industry, the processing of annealing-resistant inks and hot-signing inks is an important requirement that the REA JET spray mark system reliably meets. With this advanced system, large lettering can be produced automatically - a perfect alternative to conventional stencil technology and marking pens.

The spray mark blocks are controlled via the REA JET TITAN Platform, REA's uniform and cross-technology operating concept. This intuitive platform makes it possible to efficiently manage and control various coding and marking technologies.

Our REA JET ST marking block system is suitable for versatile applications in industrial coding and marking. Here are some examples of applications:

- Alphanumeric marking

- Two-line marking with logos and 2D Codes

- Marking with hot-signing ink, annealing ink and high-temperature resistant ink

- Marking under extreme conditions

- Good recognition and readability of the marking from a great distance

- Marking with fluorescent and UV paints

- Sealing with protective lacquer

- Metered application of oils and release agents

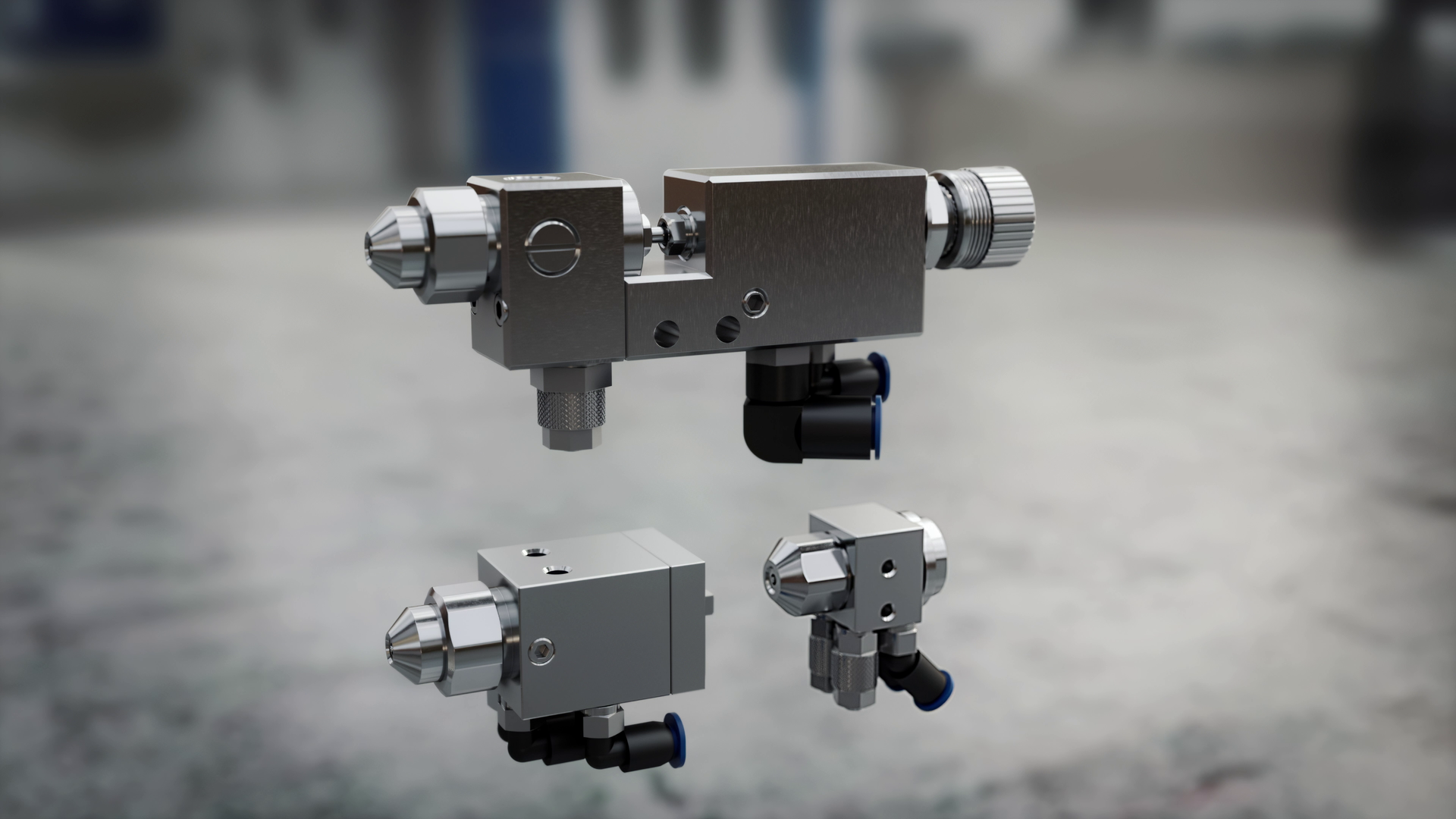

REA JET ST SRE-10 spray mark block

Electrical control

The REA JET ST SRE-10 spray mark block with electric control sets new standards in industrial product marking and offers numerous advantages:

- Innovative electric actuation: the electrically controlled needle stroke enables precise and reliable control of the writing process, resulting in improved overall performance.

- High speed: With an impressive writing speed of up to 200 m/min, the SRE-10 enables efficient marking.

- Minimal downtime: The very fast nozzle and needle change drastically reduces maintenance time and maximizes productivity.

- Increased durability: Thanks to its robust design and electrical control, the SRE-10 has a long service life, which reduces the total cost of ownership.

- Integrated cleaning function: The writing block has integrated flush valves that enable automatic cleaning, keeping reliability and print quality consistently high.

REA JET ST SRP spray mark block

Pneumatic control

The REA JET ST SRP spray mark block, available in the SRP-7, SRP-10 and SRP-16 models, with pneumatic control is a proven system for industrial marking tasks and offers the following decisive advantages:

- Reliable pneumatics: the pneumatically controlled needle stroke ensures precise and consistent marking quality, even under demanding production conditions.

- Efficient speed: With a marking speed of up to 75 m/min, the SRP is ideal for medium-speed production lines and guarantees excellent marking quality.

- Outstanding dot quality: The SRP stands out for its particularly high dot quality performance, resulting in clearly readable markings.

- Optimized air control: The integrated internal control for the atomizing air enables fine tuning of the spray pattern and contributes to uniform, precise application.

- Proven technology: As an established system for many years, the SRP has proven its reliability and efficiency in a wide range of industrial applications.

Discover the numerous possible applications of our powerful REA JET ST 2.0 marking system, which you can use to ensure print quality in your industry.

Suitable for precision line and dot marking as well as surface application of a wide variety of high and low-viscosity media.

The REA JET ST marking system sets standards in spray mark technolgie and offers companies a versatile and robust marking system. Whether in industrial production or in the heavy industry sector - the REA JET ST marking block system impresses with its performance capability and efficiency.