REA JET DOD 2.0

Large character inkjet printer

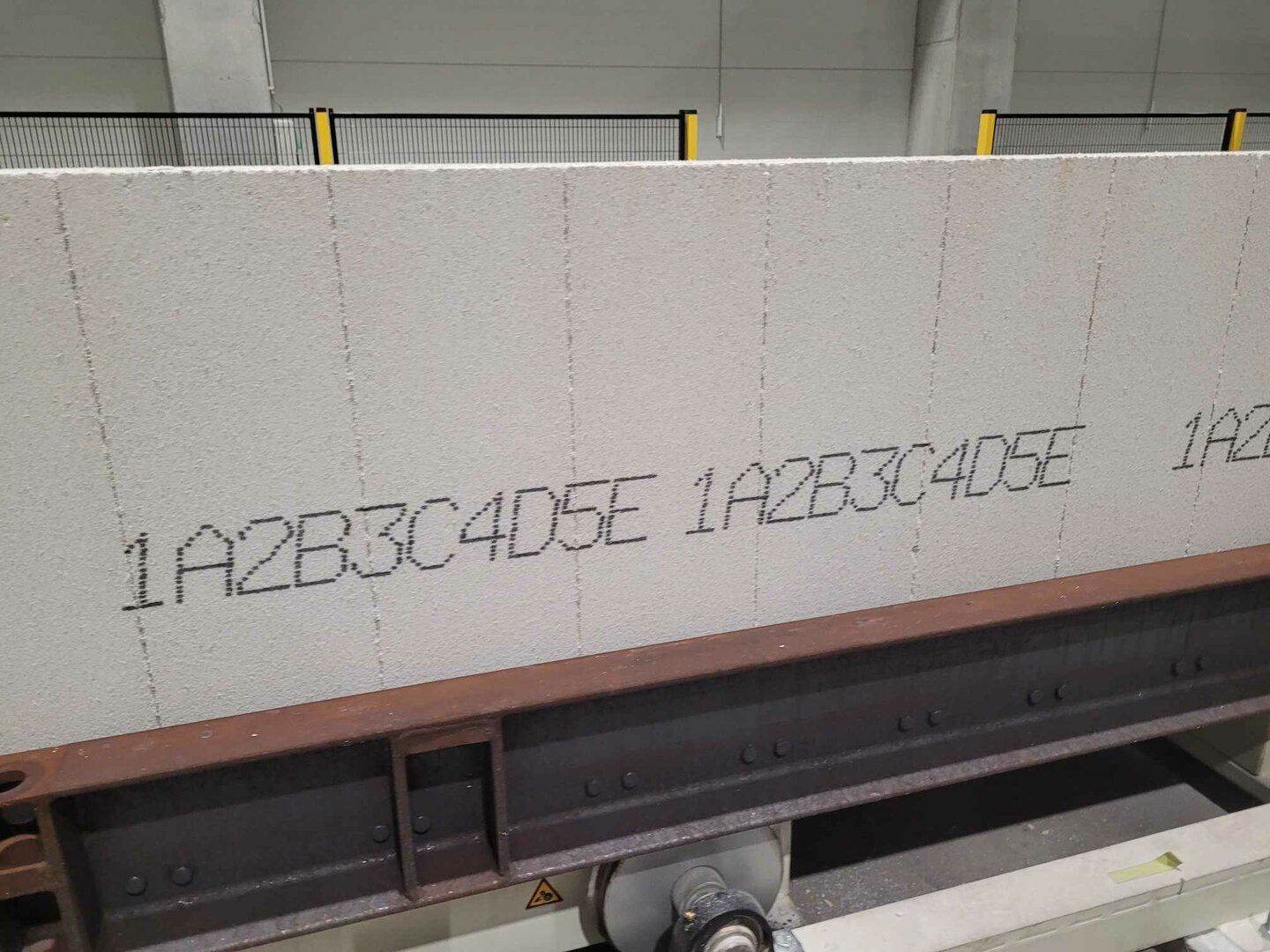

Large, clearly readable markings, on-demand ink consumption and use in extreme environmental conditions - that's our latest generation REA JET DOD 2.0 Large Character Inkjet Printer. With our robust printing system, which is based on innovative drop-on-demand printer technology, you can print text, data and logos in impressive sizes of up to 140 mm per print head.

REA JET DOD 2.0 is an outstanding inkjet printing system designed especially for use in rough industrial environments. With its advanced drop-on-demand technology, it enables precise and reliable printing.

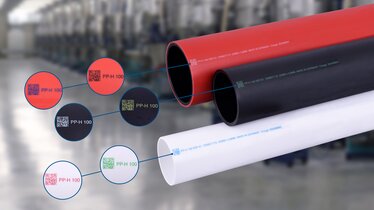

Absorbent and non-absorbent surfaces can be easily marked with text, variable data or logos using individually controllable nozzles up to a font height of 140 mm per print head and a speed potential of up to 600 m/min. If larger lettering images are required, the print heads can be combined.

Extreme environmental conditions such as dust, moisture, heat or cold are no problem. The printing system tolerates vibrations and temperature fluctuations from minus 5° to plus 45° C. Thanks to its modular design and intuitive operation, the drop-on-demand printer is highly flexible.

Our robust REA JET DOD 2.0 Inkjet Printer is suitable for a wide range of industrial coding and marking applications. Below you will find some examples of areas of application:

- Under extreme environmental conditions such as dust,

Humidity, vibration and temperature fluctuations - Alphanumeric texts, codes and logos

- Variable data such as date, time, counter, shift code and database content

- Large-area logo printing by cascading the print heads

- Absorbent and non-absorbent surfaces such as: Paper, cardboard, metal, glass, ceramic, stone, wood, plastic, rubber, foils, carpet, textiles, non-woven fabric, organic surfaces etc.

- Primer coating for pre- or post-treatment (absolutely mist-, aerosol- and loss-free local application)

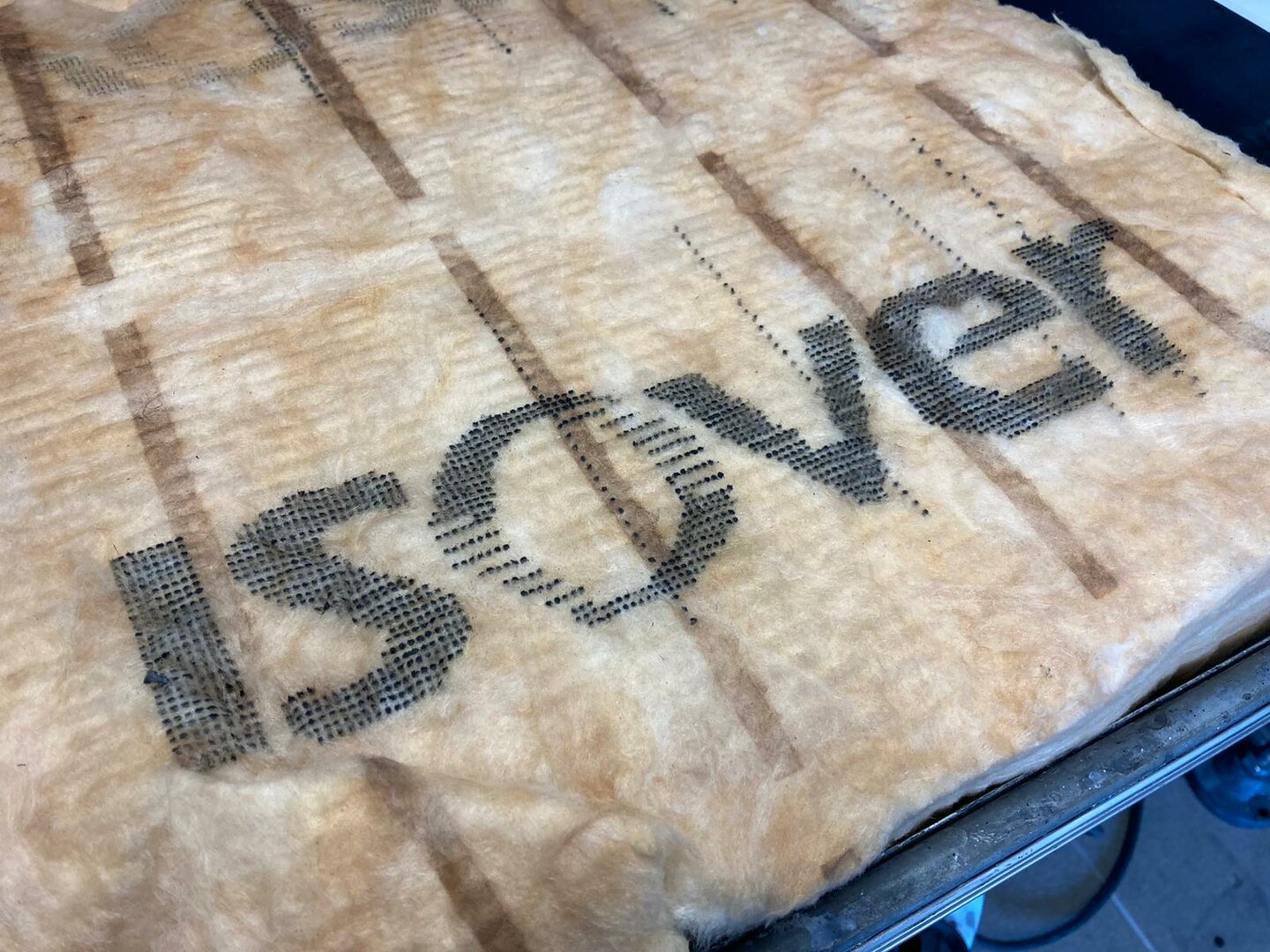

Marking filled and unfilled bagged goods

Bag marking of bulk goods

The marking of sacks and bagged goods has to be carried out efficiently and reliably without compromising on the print quality of the marking. The marking of bags - filled or unfilled - with bulk goods is often carried out under harsh and difficult technical conditions. High dust content, temperature changes or vibrations are the norm rather than the exception. Despite these challenging environmental conditions, high-contrast and perfectly legible print results can be easily achieved with the REA JET DOD 2.0.

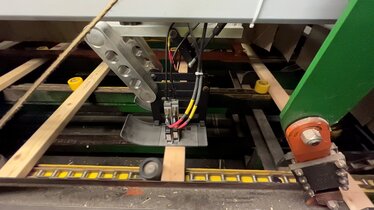

Mist- and aerosol-free

Application of lubricants

To ensure that only the necessary amount of lubricant is used when wetting dots, lines or surfaces, we have developed a solution especially for blanks and coil wetting in metal forming. Our lubricants are environmentally friendly and offer practical advantages at the same time.

Our REA JET DOD 2.0 enables absolutely mist-free, aerosol-free and loss-free local application of lubricants. The lubricant is only applied where it is needed. The system is perfectly suited to drastically reduce lubricant consumption in versatile applications and to carry out production processes fully automatically and cleanly. With this method, each component can be precisely calculated in advance.

Discover the numerous possibilities offered by our powerful REA JET DOD 2.0 coding and marking system to ensure precise and reliable printing under extreme environmental conditions.

Our REA JET DOD 2.0 Large Character Inkjet Printer offers impressive performance for industrial coding and marking. With the ability to print text, data and logos up to 140mm in height per print head, this system meets the needs of a wide range of applications. The printer's resolution is especially optimized for industrial environments to ensure clear and accurate results.