Tailor-made marking concepts for modern packaging

REA Elektronik will be presenting pioneering coding and marking solutions for the packaging industry at Fachpack 2025. From 2D Codes and sustainable technologies to innovative laser systems - discover the future of packaging.

Mühltal, July 10, 2025 - The packaging industry is constantly developing new concepts to package products even more efficiently, sustainably and smartly. Keeping pace with new regulations such as the Digital Product Passport (DPP) or the provisions of the EU Packaging Ordinance (PPWR) as well as technological developments and consumer expectations requires innovation and personal exchange between many experts. Platform for the industry: Fachpack 2025; an important network partner: REA Elektronik with its individual coding and marking solutions - and also innovations such as a powerful 100 watt laser system and the marking of recyclable monofilms.

Modern packaging combines technological advances, sustainability and design. With REA Elektronik, your marking is more than just printers or labelers. It is sophisticated and consistent processes, system integration and customized solutions that meet the requirements of industry, trade and legislation. REA will show visitors to Fachpack 2025 how this works as a full-range supplier that accompanies customers along the entire production line with its marking and code verification technologies - open to technology, practical and future-proof.

Advice in the 2D Competence Center

2D Codes are one of the top topics in the packaging industry and at Fachpack 2025. They will permanently change the retail sector and bring more transparency, more efficient processes and better customer information. GS1 Germany is the driving force behind the changeover from 2027. The pharmaceutical industry has already successfully mastered the change. As its companion and one of the market leaders in pharmaceutical serialization, REA is also an experienced partner for retailers in the cost-efficient migration to GS1-compliant 2D Codes, including integration into existing lines. At Fachpack, REA experts, partners and independent industry experts will be available in the 2D Competence Center to provide open and practical advice on topics such as standards, line integration and code quality. There will be many live presentations at the REA stand every day.

PPWR, DPP and sustainability

The new EU packaging regulation (PPWR) requires more resource-efficient packaging from 2026 and therefore massive changes for the industry. REA shows how these challenges can be translated into productive solutions: with environmentally friendly inks, consumable-free laser coding, recyclable materials, durable and robust systems and end-to-end data integration. REA also actively supports the Digital Product Passport (DPP) - with systems that are equipped for future requirements. For example, digital direct printing can replace pre-printed packaging, reduce storage costs and waste, while at the same time enabling individual print layouts in real time - efficiently, flexibly and ecologically.

REA customers have a choice. Because labeling solutions are also part of the portfolio. REA provides advice that is open to all technologies and works with customers to find the right solution from an economic and regulatory perspective.

With code verification systems from REA VERIFIER, customers can reliably determine whether the applied codes are complete, readable and comply with standards.

Product news at Fachpack

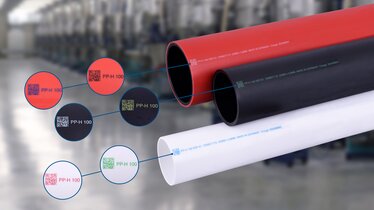

Laser marking is permanent, consumable-free and virtually maintenance-free in operation. The new REA Laser CL100 with 100 watts is even more powerful than the standard lasers in the REA LASER CL series. This makes the CO2 Laser faster, stronger and gives it more power reserves. The newcomer is especially designed for harsh environmental conditions. It marks packaging made of cardboard, paper, glass, plastics and foils with text and graphics of all kinds up to a marking field size of 250 x 250 millimetres - including dynamic text fields. The marking is produced contact-free, precise, fast, secure and, depending on the requirements, by engraving, color change or color removal.

In terms of improved recyclability, REA also offers modern coding and marking solutions for marking monofilms with UV inks and especially laser systems.

Especially for the marking of consumer goods with a fast rotation of goods (Fast Moving Consumer Goods, FMCG ) REA presents a scan-print-read turnkey solution. Automated data transfer to the controller of the printer unit and automatic teach-in of the integrated camera ensure that both plain text and codes are verified for readability and content immediately after printing. This ensures that the right information and the correct code are applied to the right product.

There is also news from the REA LABEL ES product line. The REA ColorJet 2 full-color inkjet printer with 1:1 printing and dispensing function is now available in various versions. It is also suitable for use in automation systems. The system is complemented by an external display that offers improved visualization and greater ease of use. Among other things, it shows the fill levels of the cartridges and serves as a clear touch user interface.

PackTalk and drinks: After work at REA

To kick off the trade fair, REA invites you to a get-together at the REA booth under the motto "PackTalk and Drinks" on September 23 from 6 p.m. to bring industry experts, partners and interested parties together in a relaxed after-work atmosphere.

Experience REA from September 23 to 25, 2025 at Fachpack 2025 in Nuremberg: Hall 1, Stand 1-233.