Logos and seals of approval as desired and required

Direct marking is becoming increasingly important in the timber industry. Holzwerk Baur and the coding and marking specialist REA JET have implemented customized solutions for this using laser and inkjet technology.

Direct marking is becoming increasingly important in the timber industry. The market not only expects correct markings in accordance with relevant safety guidelines, sorting classes and import regulations. Individual customer requirements such as dimensions, barcodes or the company logo also need to be met. Holzwerk Baur and the coding and marking specialist REA JET have implemented tailor-made solutions for this using laser and inkjet technology.

The wood comes from responsibly managed forests within a radius of 100 kilometers - and is shipped all over the world in various forms. Every tree that comes to Holzwerk Baur in Wain, Baden-Württemberg, is processed almost completely by the 85 employees. 180.000 solid cubic meters per year or 1,200 per day leave the plant as planed timber, sawn timber, garden timber or construction timber, as bark mulch, wood chips or sawdust. Some of the wood shavings are used to fire the company's own heating plant. "Our product depth has increased in recent years," says Frederik Baur, who manages the business together with Hermann Baur. "To create greater added value, we have invested in processing companies in particular." Sustainability is important to the ISO 500001-certified traditional company, which was founded in 1906 and is now run by the fifth generation of the Baur family - as are permanent, trusting and long-standing relationships with suppliers and customers.

All of this played a role when Baur planned its new plant for construction timber (KVH) and put it into operation in 2015. The compact finger-jointing machine from SMB cuts around 1,250 pieces of timber every day. Each one is marked on the front, depending on the customer, with a wide range of information - from company logos and trade shows to quality seals, CE and IPPC markings. "Our customers are active in the timber trade and the wood processing industry - with a wide variety of applications and sales markets and their respective required stamps and markings," reports Baur. "This also includes the US market with its especially strict sorting standards. Every single piece has to be marked with the appropriate quality label." Scanner-readable barcodes are also required - a challenge for any printing technology, especially with the individually grown natural material wood. What was needed was a highly flexible, reliable and sustainable solution.

"Rarely is one machine the same as another"

Baur found this at REA JET. The timber plant has been working with the South Hessian specialist for industrial coding and marking solutions for many years - and was once again able to rely on its experts and product diversity for the KVH plant. "As a full-range supplier, we have the advantage of being able to develop individual concepts for each customer," says Michael Jäger, sales representative specializing in wood at REA JET. The portfolio includes versatile printing technologies and systems for a wide range of requirements, surfaces and industries - from large character inkjet printers to small character printers for the intricate marking of product packaging. Special solutions are often required in wood processing in particular, as the production lines in the plants are usually adapted to the local conditions and individually developed over the years. "Rarely is one machine the same as another."

In addition, the requirements for marking in the wood industry have changed significantly in recent years. "In the past, a label was attached to the roof batten, which was removed on site and stuck to the documents - but this could get lost. In digital times, this procedure is no longer necessary," explains Jäger. "In addition, today all timbers have to be marked, whereas previously this was only required for two in a bundle. A high-quality direct marking can perform all of this: once applied, it stays where it is." Modern markings are also interesting for marketing: "If you see a truck on the highway with a pile of wood on which the company logo is emblazoned across a large area, it immediately sticks in your mind." The required traceability is also guaranteed by permanent, reliable markings on each individual timber.

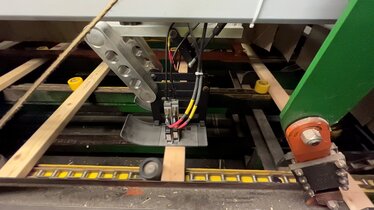

For the new KVH plant in Wain, the choice fell on the 60 wattREA LASERCO2 Laser CL. It is robust, consumable-free and works reliably, even under the most adverse conditions such as temperature fluctuations, humidity, dust pollution and vibration - and it also leaves reliable and permanent markings on difficult surfaces.

Marked in seconds

When the laser places its marking on the wood, a small cloud of smoke rises, which is immediately extracted. Otherwise, not much can be seen of the work of the well-housed system. "For us, the marking laser with the required safety standards was new territory. REA JET was a great support with its comprehensive and personal support," Frederik Baur looks back and adds: "The result is great. The wood is marked in a matter of seconds, we get great print images and, above all, we appreciate the versatile nature of the system." Together with Baur, REA JET developed a series of print layouts before commissioning. Production Manager Safet Stiller and his employees now assign these to each order via the production control computer, as the laser system communicates directly with the woodworking machine via an interface.

All REA JET Systems can be integrated into production according to the company's individual requirements and development status. The possible applications range from stand-alone solutions to integration into a fully automated production line - thanks to state-of-the-art interfaces, the REA JET Systems are fully Industry 4.0-compatible.

The REA JET TITAN Platform, which Baur uses to control the laser system, is also designed accordingly: it can be integrated into the company network and operated using a PC, tablet or smartphone. Its integrated remote maintenance tool can be used to request diagnostics and assistance if required. The REA JET TITAN Platform can also be used to operate all REA JET coding and marking technologies. An advantage that comes into play at Holzwerk Baur. This is because another ink-based coding and marking system based on cartridges from REA signs in its planing mill: the REA JET HR Inkjet Printer. Like the laser system in the KVH plant, this is operated via the TITAN platform - which is also advantageous for the employees: they only had to be trained once for both coding and marking systems - and when operating them, they do not have to keep thinking about which device they are currently standing at and which printing technology they are currently working with.

Ink for the planing mill

In the planing mill, the REA JET HR Inkjet Printer works with two print heads due to the size of the marking required. They can be combined precisely and accurately to produce a seamlessly uniform print image. "Ink is currently the most suitable technology for planing," says Michael Jäger. The high-resolution inkjet printer now uses two print heads to mark two pieces of wood freshly produced in the Waco planer with the CE marking at the same time - a total of 8,500 pieces per day. The print heads work from bottom to top - and deliver the best print quality with a resolution of up to 600 dpi that can be set in 16 levels. The operators retrieve the pre-designed print layouts and content from the TITAN platform library and assign them to the respective products and production orders. To prevent surprises, the cartridge fill levels are permanently displayed. With every new cartridge, a new printing unit is also available. This makes the Inkjet Printer maintenance-free. And since the REA JET customer advisors are permanently on the road anyway, the new cartridges are never long in coming, even if they are notified at short notice.