Modern plastics, high-quality and variably marked

REA presents its solutions for industrial coding and marking and code verification at the K trade show - "Identifiability, traceability and a more sustainable future"

Mühltal, August 29, 2025 - The circular economy and digital transformation as industry drivers are top themes at K 2025, the world's leading trade fair for the rubber and plastics industry. With its solutions for industrial coding and marking and code verification, REA Elektronik supports suppliers and manufacturers worldwide as a reliable partner in digitalization, better traceability and greater sustainability. The trade show motto of the company from southern Hesse is accordingly: "We mark for identification, traceability - and a more sustainable future."

Directly marked plastic products and packaging bear machine-readable codes and alphanumeric texts until the end of their useful life and can then be recycled by type. REA's systems, which can be integrated into existing production processes, apply this information reliably, correctly, in high quality and with permanent readability, even on difficult surfaces. More than 500 standard and special inks or laser light for the application also save costs and logistics for labels and disposal of the carrier materials.

Suitable concepts for individual requirements

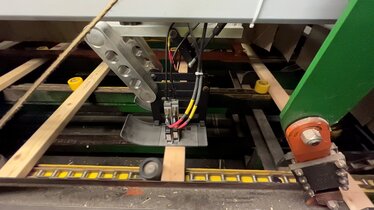

The experts at REA Elektronik work with extruders, injection molders, compounders and suppliers of plastic packaging to develop the right concept for individual requirements. Be it with the REA JET SC 2.0 small character inkjet printer for the razor-sharp display of small codes or markings on products with curvatures, grooves or indentations. Or with the "wet-on-wet" printing technology of the REA JET HR 2.0 inkjet printer, which uses a double print head to print machine-readable codes and plain text on smooth, transparent and dark substrates: the first print head prints a white ink mirror, which the second immediately prints with black or colored ink before the two dry together. Laser marking is also an option: using the power of bundled light, the REA LASER Fiber Laser FL prints texts, codes and markings of all kinds with variable data on pipe surfaces made of high-performance plastics or metal or even plastic parts from injection molding production. Color change in the material itself, partly due to laser-sensitive additives incorporated into the plastic, permanently bonds the markings to the product.

Marking monomaterials - knowing how

From 2026, the new EU packaging regulation (PPWR) will require a more resource-efficient use of materials. The "design for recycling" principle requires the industry to make massive changes, including switching to monomaterials. They consist of just one type of plastic and are therefore much easier to recycle than traditional multi-layer composite materials. This poses an enormous challenge for product marking, as monomaterials and foils have a lower surface tension, which means that inks adhere less well to them.

The experts at REA know how these challenges can be translated into productive solutions and how monomaterials can be made sustainable, high-contrast and permanently printable in order to reconcile regulatory requirements and recyclability. And it does so with recyclable materials, end-to-end data integration and durable and robust systems that suit the customer's individual production environment and situation. Among other things, the REA JET HR 2.0 inkjet printer meets these requirements with the wet-on-wet process described above as well as special inks that cure under UV light and leave a razor-sharp, permanent and, if desired, colored marking on foils and other plastic surfaces.

REA JET Titan - one operating platform for all systems

All REA JET Systems can be operated via the REA JET TITAN Platform. In combination with the REA Verifier systems for code verification and inline inspection, they provide reliable turnkey solutions for plastics and rubber marking. This saves time and money through a lower error rate, reduced training requirements and easier personnel deployment.

Visit REA Elektronik at K 2025, the international trade show for innovations in the plastics and rubber industry, from October 8 to 15 in Duesseldorf: Hall 4, Stand C22.