Latest news from the world of marking, labeling and code verification systems

In our news section, you can find out everything you need to know about the latest developments, technologies and trends in the field of industrial coding and marking. Stay informed about innovative solutions, best practices and important information.

Filter for categories

Trade show

Sophisticated concepts for industrial coding and marking and code verification

Trade show

High-quality marking, code verification and wetting for sheet metal production

Trade show

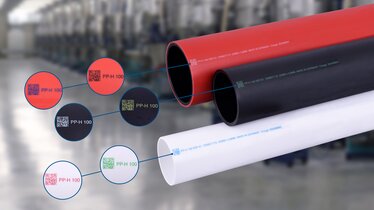

Modern plastics, high-quality and variably marked

Trade show

Sustainable retrofitting of printing presses for customized content

Products

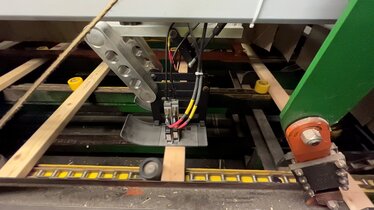

Heavy duty impact protection for REA JET HR: Unsurpassed safety in the wood industry

News

Tailor-made marking concepts for modern packaging

News

The new REA JET ST SRP-10 electrically controlled spray mark block

News

Reliable marking for the wood value chain

News

Change of management at REA Elektronik heralds a new era

News

Quality first - A must also in the marking of high-quality pharmaceutical and medical products

News

Sustainable, individual, reliable: logistics marking from REA

Blog

Pre-announcement: REA LASER LC400 laser cabin