Sophisticated concepts for industrial coding and marking and code verification

REA Elektronik will be presenting sophisticated solutions for direct printing, labeling and code verification at LogiMAT 2026. Highlight: the new REA Print-Inspect complete package for standard-compliant marking and 100% quality control.

Sophisticated concepts for industrial coding and marking and code verification

Mühltal, January 26, 2026 - State-of-the-art technologies for high-quality marking and reliable code verification are REAElektronik's specialty. The full-range supplier will be showcasing its sophisticated systems that make the difference at LogiMAT 2026 - in line with the new trade fair motto: "Passion for Details". This includes the new "REA Print-Inspect" package.

REA Elektronik has an eye for the big picture: "Our coding and marking technologies from the REA JET line for direct printing and REA LABEL for labeling can be seamlessly integrated into any existing production process," says Frank Debusmann, Sales Director national. "And with the standard-compliant quality assurance provided by the code verification systems from the REA VERIFIER line, it's a well-rounded solution for manufacturers." This is in line with the motto of LogiMAT 2026, which Exhibition Director Michael Ruchty said at the launch: "With Passion for Details, the trade show demonstrates that it's not just the big solutions that count in logistics, but also the small, well thought-out systems that make the difference."

REA will be presenting its latest all-round carefree solution for industrial companies at LogiMAT 2026. The complete "REA Print-Inspect" package combines high-resolution printing with reliable result control: the high-performance REA JET HR 2.0 inkjet printer, which produces print images up to 25.4 mm high, and the integrated camera for immediate inspection of the marking are controlled via the user interface of a panel PC using special software. Thanks to the 100% quality check in real time, the system immediately detects possible printing errors. This optimizes the quality of 1D and 2D Codes, improves the first-pass reading rate and helps to comply with legal requirements - including international standards, GS1 standards and other specifications. The system also performs an important role in reducing costs, as it reliably prevents expensive recalls due to faulty codes and poor printer quality.

At LogiMAT 2026, REA will also be showcasing further technologies and innovations from its comprehensive range with an excellent international reputation, which is developed and manufactured in Germany.

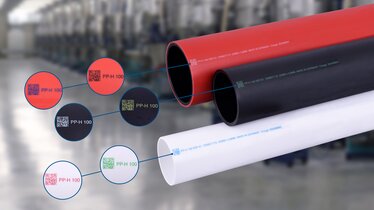

Direct marking with REA JET UP for recyclable packaging

"The EU packaging regulation (PPWR) is currently driving all of our customers," says REA expert Debusmann. "This is because its implementation will also put coding and marking technologies to the test."

Direct marking is the solution if packaging has to be resource-saving and as recyclable as possible from summer 2026. Digital printing also stands out with its very low cleaning requirements and is available for years without wear and tear - whereas with other printing processes, such as flexography, the printing tools have to be cleaned regularly and wear out over time.

The all-rounder REA JET UP on a piezo basis is recommended for digital direct printing. UP stands for "Universal Print", because with its innovative technology, the printing system is suitable for high-contrast and reliable marking of attractive and informative secondary packaging - regardless of whether it is made of paper, cardboard or wood, coated or finished, absorbent or non-absorbent materials. A wide range of inks are available for this - from oil-based and slightly solvent-based to UV-curing for substrates on which no other ink would dry.

REA LABEL pallet labelers: important information on up to three sides

The REA LABEL pallet labelers offer the greatest flexibility in marking. Depending on the model, they print A4 or A5 labels in portrait or landscape format and apply them to up to three sides of the pallet in throughfeed or at a standstill. Thanks to their modular design, they fit seamlessly into the production process.

Fast and reliable: the REA LABEL high-speed servo labeler

With high print quality and dispensing speeds of up to 2,500 labels per hour, the servo-electric REA LABEL ES high-speed servo labeler significantly increases the level of automation in production: it automatically detects shipping containers with varying heights and places the labels in exactly the right place using contact-free compressed air. With its modular and compact design, it can be individually adapted to customer requirements and local conditions.

Cost-effective in-house solution: color labels from the REA LABEL ColorJet 2

Whether in production, logistics or automation - wherever high-quality color labels are needed "on demand" for industrial use, the REA LABEL ColorJet 2 is at its best. The compact color label printer with its robust, powder-coated housing is a cost-effective alternative to an external print shop for small to medium print volumes. It prints small and medium quantities of labels in full color, either individually or in series, with a print width of up to 21 centimeters and the highest resolution of up to 1,200 dpi.

It comes in three versions. With the standard REA LABEL ColorJet 2S model, the label can be removed manually using a tear-off edge. The REA LABEL ColorJet 2C cuts labels individually or after a print job using a circular knife. The REA LABEL ColorJet 2P can print and dispense labels 1 to 1 in full color. The backing paper is rewound by an external rewinder. This system can be used for manual workstations, fully automated applications or in cooperation with a robot system. It has a flexible PLC I/O interface.

All REA labeling systems can be operated with commercially available print modules (including those from Novexx, CAB, SATO and Zebra).

Expert presentation in the "Exhibitor Insights" supporting program

Trade fair visitors can use the presentation by Frank Debusmann, Sales Director national, in the LogiMAT supporting program as an introduction to the world of possibilities offered by REA. In the "Exhibitor Insights" event series, he will provide insights into "PPWR, direct marking & wet-on-wet: paths to future-proof packaging marking" on Thursday, March 26, 2026, from 1 p.m. in Forum North, Hall 7, Stand 7C65.

Experience REA from March 24 to 26, 2026 at LogiMAT 2026 in Stuttgart: Hall 2, Stand 2A11.