UDI - an opportunity for process optimization

Is this the right heart valve? How old are the surgical instruments? UDI marking will answer these questions in the future. It presents manufacturers with new challenges, but also offers the opportunity to completely restructure processes and increase efficiency.

Is this the right heart valve? How old are the surgical instruments? UDI marking will answer these questions in the future. It presents manufacturers with new challenges, but also offers the opportunity to completely restructure processes and increase efficiency.

Unambiguous product identification is required in almost every industry. Manufacturers and consumers want maximum transparency and traceability. The European Union is currently introducing UDI marking (UDI = Unique Device Identification) for medical devices. The system has been agreed and recognized with the USA via the International Medical Device Regulators Forum (IMDRF).

UDI is intended to provide information about the origin and properties of a medical device throughout its entire product life. In accordance with EU Regulation 2017/745, medical devices sold in the EU should be clearly identifiable by the end of December 2028. The deadlines in the Medical Device Regulation (MDR) are based on whether medical devices are assigned to classes with a high, medium or low risk. Those with a high risk (e.g. artificial joints or heart valves) have had to be marked since May 2021, in vitro diagnostics since May 2022. The deadlines have been extended for the other classes. Depending on the product type, medical devices with medium risk (e.g. anaesthesia or hearing aids) and low risk (e.g. walking aids and bandages) will have to be UDI-marked from the end of December 2027 and the end of December 2028 respectively.

The aim is to improve patient safety. However, UDI involves a lot of effort and is a challenge for manufacturers with a wide-ranging portfolio. However, the deadline extension offers the opportunity to go beyond mere compliance with regulatory requirements and to optimize logistics and sales processes in the course of the changeover, thereby increasing the quality, safety and efficiency of the entire product range.

DI+PI = UDI

The front part of the UDI consists of the Device Identifier (DI) and the back part of the Production Identifier (PI). As a globally unique article number, DI prints the static properties: product, manufacturer, risk class. It is defined with the help of four allocation bodies that have been accredited by the EU Commission: GS1, HIBCC, ICCBA and IFA.

The manufacturing identifier PI prints the variable data of the medical device for individual identification: manufacturing or expiry date, batch or lot number, serial number, etc. In the central database Eudamed (European Databank on Medical Devices), which is currently being set up, every manufacturer has to register each medical device with its UDI before importers or distributors as well as pharmacies, clinics or medical practices verify and complete the data. This is how Eudamed is to document the properties of each product. The counterpart to the Eudamed database in the USA is the GUDID (Global Unique Device Identification Database), the database of the American health authority.

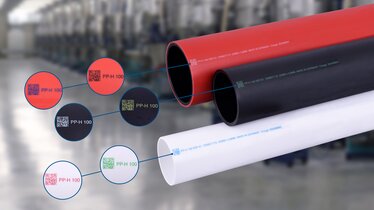

To this end, manufacturers have to provide each medical device or its packaging and container packaging with UDI - well positioned and at least in duplicate: as human readable text and machine-readable 1D Code or 2D Data Matrix code. This can be done with ink, laser or label. If there is not enough space, the human readable text can be omitted.

Decisive: the choice of printing technology

The versatile materials of medical devices and packaging pose a challenge for marking. To ensure that the UDI remains reliable and permanently well readable, the choice of printing technology is crucial.

Laser marking processes are particularly suitable for direct marking of plastic or metal, but also achieve very good results on paper folding boxes. With the help of a powerful laser, a color change is caused in the material itself, from light to dark or vice versa (color change) or ink is removed to expose the substrate behind it (ablation).

For a good result, the following parameters have to be coordinated: Pulse duration, pulse spacing and possibly modulation of the laser beam; wavelength; focusing of the laser beam; speed of the production line. The material also has a very strong influence. Paper types with certain surface finishes (kaolin or calcium carbonate) can impair the marking capability. WithCO2 Lasers, wavelengths around 10.6 µm work less well on simple paper types with calcium carbonate as a filler, while 9.3 µm achieves significantly better results with both fillers. The REA JET CLCO2 laser system marks folding boxes permanently and with high precision, while the REA JET FL fiber laser system marks metals such as stainless steel and titanium, plastics and thin foils.

Inkjet Printers are often integrated into the production line for the serialization of packaging. In all processes, the print heads keep their distance from the material, whereas thermal or thermal transfer print heads are always in contact with it.

Thermal inkjet printing processes have a heating element in the nozzle that creates a vapor bubble that ejects the ink droplet. The process is therefore called "thermal inkjet" (TIJ). In industry, cartridges with integrated print heads from Hewlett Packard are often used. These print up to 700 meters/minute fast, typical speeds are around 100 to 200 meters/minute.

These systems are preferred for marking absorbent materials with water-based inks, such as folding boxes that are unvarnished at the marking position. The further development of solvent-based inks has significantly expanded TIJ's field of application: It can now also be used to mark non-absorbent materials (foils or metal). Disadvantages are the low print height of just 12.7 millimeters and the short distance between the print head and the marking surface.

The advantages of the TIJ are the high resolution and print quality. For example, the REA JET HR 2.0 inkjet printers print at up to 600 dpi vertically and 1,500 dpi horizontally at product speeds of up to 762 meters/minute on absorbent and non-absorbent surfaces. The combination of two print heads enables print heights of up to 25.4 millimeters. The new wet-on-wet printing process - creating and immediately marking a colored field - marks non-absorbent dark or transparent surfaces (foils, plastic and metal) in a high-contrast and clearly readable manner.

TIJ is also suitable for Tyvek. The plastic fibre material allows hot steam to pass through so that packaged medical products can be sterilized. As the fiber structure and permeability cause ink to run unevenly, it has to dry fast and adhere well.

Piezo inkjet printers work with a piezo crystal in the nozzle. This changes its shape at lightning speed under electrical voltage and ejects drops of ink onto the print surface. In the industry, print heads were often found that work with oil-based inks and deliver print images with a low resolution of around 100 dpi and heights of up to 100 mm. This technology is less suitable for the serialization of small folding boxes, but is more suitable for marking transport cartons. Newer developments such as the REA JET UP provide shipping units with content that previously had to be printed on labels, with high print quality and edge definition. Its new patented and fast-drying ink formulation also enables high resolution direct printing on the surfaces of coated cartons.

Where direct marking is not possible or undesirable, labels are used. They are usually created using thermal transfer printers, in which the heating element in the print head transfers the ink from the ribbon to the label. Depending on the choice of label and print ribbon, the printed images can be of high quality and durability. REA LABEL systems offer two options for marking shipping units of all sizes at different locations: They apply pre-printed labels or print, dispense and apply labels as complete print and apply systems.

Don't forget: checking the code quality

Faulty, recalled or expired medical devices can only be identified fast if the UDI is correct and legible. Manufacturers should therefore ensure that the marking is correct and error-free, that its content is correct and that its quality complies with international standards. This cannot be done with handheld scanners, which are significantly more error-tolerant than permanently mounted scanners.

The ISO/IEC 15415 and ISO/IEC 29158 standards form the basis for the inspection of UDI markings. The most important test parameters include Symbol contrast - maximum difference between dark portions and light portions of the code or carrier material; Modulation - uniformity of reflections in the light and dark module areas of the 2D Code; Fixed pattern damage - examination of quiet zones in the 2D Code that are without user data but are used for position recognition and as an auxiliary size; Code size (module size) - "pass" for a sufficient size or "fail". Especially code verification systems such as those from REA VERIFIER help manufacturers with the metrological, qualitative assessment of their UDI markings, stationary, mobile or integrated into production.

For manufacturers of medical devices, it is time to get active when it comes to UDI and find individual solutions with an experienced partner - from code development to suitable marking processes and code verification. As a full-range supplier, REA Elektronik is ready to support the industry in this task with its REA JET, REA LABEL and REA VERIFIER lines. Industry 4.0-compatible systems that can be seamlessly integrated into existing production lines are indispensable for individualized product marking. They also offer manufacturers the opportunity to prepare for the future with modern marking processes for optimized internal and external workflows.

PUBLISHED BY

Wilfried Weigelt

Head of Department

REA Verifier

REA Elektronik GmbH