Identification for intralogistics and production from REA - customized, high-performance and reliable

The full-range supplier will be presenting its marking and code verification systems at LogiMAT 2024

Mühltal, January 31, 2024 - Markings are indispensable for logistics and process management. This is an advantage when all systems for direct printing, labeling and code quality verification come from a single source - such as the full-range supplier REA Elektronik. At LogiMAT 2024, the South Hessian specialist for industrial coding and marking will be presenting its innovations and products.

Individual, reliable and secure marking is the basis for the automated control of internal and external commodity flows in modern production and is indispensable for seamless traceability. The coding and marking systems used for this purpose have to fit seamlessly into the company infrastructure and production. This is performed by the product lines of the full-range supplier REA Elektronik from southern Hesse - from REA JET for contact-free direct printing and state-of-the-art labeling solutions from REA LABEL to the REA VERIFIER code verification systems. At LogiMAT 2024, REA Elektronik will be showcasing the innovations and technologies from its comprehensive range with an excellent international reputation. The range also includes printing systems from REA JET, which have been certified by EPAL (European Pallet Organization) for marking the new "Euro pallet QR" - for the serialization of wooden load carriers and digitization of the Euro pallet pool.

A5 labels on up to three sides: the new REA LABEL PLU

The REA LABEL PLU pallet labeling systems now give users even greater flexibility in marking. Following the first version, which prints and applies A4 labels in portrait and landscape format, there is now a new variant: the A5 pallet labeler. With its compact, modular design, it fits seamlessly into production and places A5 labels on up to three sides of the pallet in throughfeed or at a standstill.

Up to 2,500 labels per hour: REA LABEL high-speed servo labeler

The REA LABEL high-speed servo labeler unleashes its full potential when it has to label differently sized packaging during shipping - and is coming to LogiMat in an even more compact version. With high quality printing and top dispensing speeds of up to 2,500 products per hour, the servo-electric dispensing applicator significantly increases the level of automation in production: it recognizes shipping containers with varying heights and places the label in exactly the right place contact-free with the help of compressed air. Thanks to its modular and compact design, it can be flexibly adapted to individual customer requirements and local conditions.

All REA labeling systems can be operated with standard print modules (including those from Novexx, CAB, SATO and Zebra).

Cost-effective and flexible: color label printing with REA LABEL ColorJet 2

The compact REA LABEL ColorJet 2 color label printer with its three variants is a cost-effective alternative to external printers for small to medium print volumes. Its compact design and robust, powder-coated housing recommend the REA LABEL ColorJet 2 for industrial use in production, logistics, automation and wherever high-quality color labels are needed "on demand". It prints small and medium quantities of labels individually or in series in full color with a print width of up to 21 centimeters and in the highest resolution of up to 1,200 dpi.

Also on show at LogiMAT: The REA LABEL 5-Color Label Printer delivers UV-sturdy and scratch-resistant labels that make the product stand out from the competition on the shelf. White in CMYK printing gives them exceptional brilliance, clarity and sharpness - whether as a single label or in runs of up to several thousand.

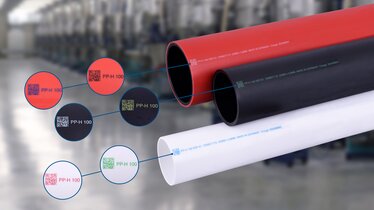

For the first time at LogiMAT: the REA JET UP for high-contrast printing on smooth surfaces

The new piezo-based coding and marking technologies REA JET UP is a multi-talent. UP stands for "Universal Print": the system prints high-contrast and reliable markings on absorbent substrates such as paper, cardboard or wood and also on smooth surfaces such as coated and finished packaging. Various inks are available for marking: from oil-based and slightly solvent-based to light-curing for materials on which no other ink would dry. This means that REA JET UP is also ideal for secondary packaging that needs to be both attractive and informative. The system prints them at print heights of up to 108 mm per cascadable print head and with a resolution of up to 1,600 dpi, so that even small characters are clearly readable.

The robust yet compact design of the REA JET UP and its suitability for Industry 4.0, which is a matter of course at REA JET, allow it to be integrated smoothly into production. And with the universal control unit for all REA JET Technologies, everything is even easier: buttons or rotary knobs have been replaced by a screen that is operated by touch, just like a modern smartphone - which is even possible when wearing gloves.

Verify codes flexibly or inline with REA VERIFIER

The code verification systems from REA VERIFIER help to optimize the print quality of 1D and 2D Codes, improve first-pass reading rates and comply with legal quality requirements - including international standards, GS1 and other specifications. They can therefore make a significant contribution to reducing costs due to faulty codes and poor code quality.

The state-of-the-art REA VERIFIER VeriCube matrix and barcode verification system verifies almost any verification pattern - whether horizontal, vertical or top-down - and can be used across all industries. The offline code verification device REA VERIFIER VeriMax Mobile enables mobile code verification in production, laboratories, incoming goods and quality assurance using a tablet PC.

Experience REA from March 19 to 21, 2024 at LogiMAT 2024 in Stuttgart: Hall 2, Stand 2A11.