Brightly colored marking of rubber tires

Brightly colored printers on rubber, lasered codes and smart labeling: At Tire Technology Expo 2026, REA Elektronik will be showing how modern marking is advancing the tire industry.

Brightly colored marking of rubber tires

Mühltal, 05 February 2026 - Brightly colored printed images on rubber or plastic, lasered QR codes and reliable labeling of products and shipping containers - at the Tire Technology Expo 2026, full-range supplier REA Elektronik will be showcasing its solutions for high-quality marking in the tire industry. The highlight: UV-curable inks for the colored marking of non-absorbent surfaces.

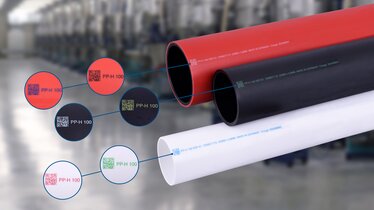

Razor-sharp images in brilliant colors on dark, non-absorbent surfaces made of rubber or plastic - this is made possible by an innovation from REA Elektronik. Using UV-curing pigmented inks, the REA JET HR coding and marking systems apply high resolution colored alphanumeric texts, logos, lettering, lines or other motifs.

Color coding with non-contact HR cartridge technology is a modern, effective and, above all, clean alternative to static systems with stamps or contacting roll coders. This is because it eliminates the need to change clichés and is maintenance-free. Each new cartridge comes with a new printing unit.

Digital data provision: individual marking and fast product changes

The innovative inks, including blue, red, green and yellow, enable digital printing in different shades that stand out from the background using the tried-and-tested white and black inks. Their pigmentation opens up the advantages of the REA JET HR systems for marking dark substrates in the best print quality: their print heads work with a resolution of up to 600 dpi that can be set in 16 levels.

The automotive and tire industries are likely to find the application interesting for reliable inline marking of elastomer and rubber products such as hoses, seals, mats and tires. The digital data provision also allows fast product changes as well as individual and serialized marking of parts with variable information such as date, time, counters, shift codes and database content. Depending on the motif, up to four print heads can be combined for multi-colored logos and markings and markings up to 50.8 millimeters high can be applied.

DOD: Raw rubber marking with special inks

Raw rubber, semi-finished products and other components for tire production are reliably and low-maintenance marked with production codes by the systems of the REA JET DOD product family. Inks especially designed for the rubber industry ensure that no residues remain in the moulds after vulcanization. The drop-on-demand printers apply alphanumeric texts, color lines for coding or type identification to finished tires. The REA JET RPS (Rubber Printing System) coding and marking system used for this was developed in consultation with the tire industry.

The robust DOD system works extremely fast and precisely on non-absorbent and absorbent surfaces, even in harsh environments - and with low maintenance requirements thanks to its low-capping print head technology.

In addition to digital printing, REA will be showcasing further coding and marking solutions from the REA JET, REA LASER and REA VERIFIER product lines at Tire Technology Expo 2026. And a new facet of the versatile application possibilities of HR printing systems, developed by trainees from REA Elektronik: they have converted HR print heads for beverage dispensing. Visitors to the REA stand at the Tire Technology Expo can get an energy boost during a busy day at the trade show with a fruit shot from the original dispenser.

Visit REA Elektronik at the Tire Technology Expo 2026, March 3 to 5 in Hanover: Stand 2026